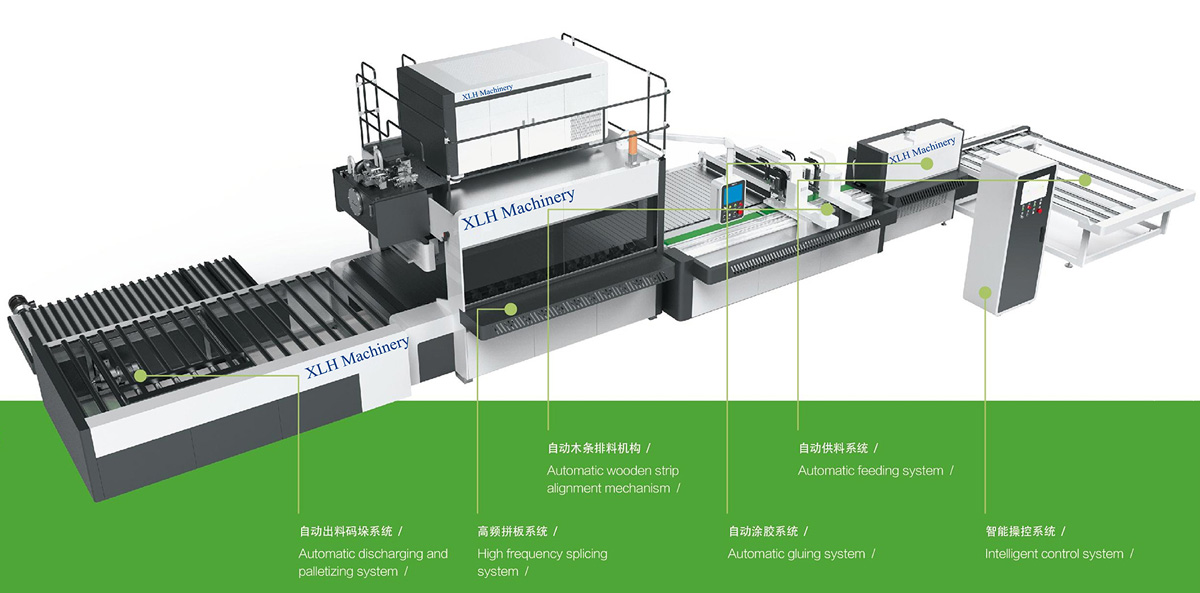

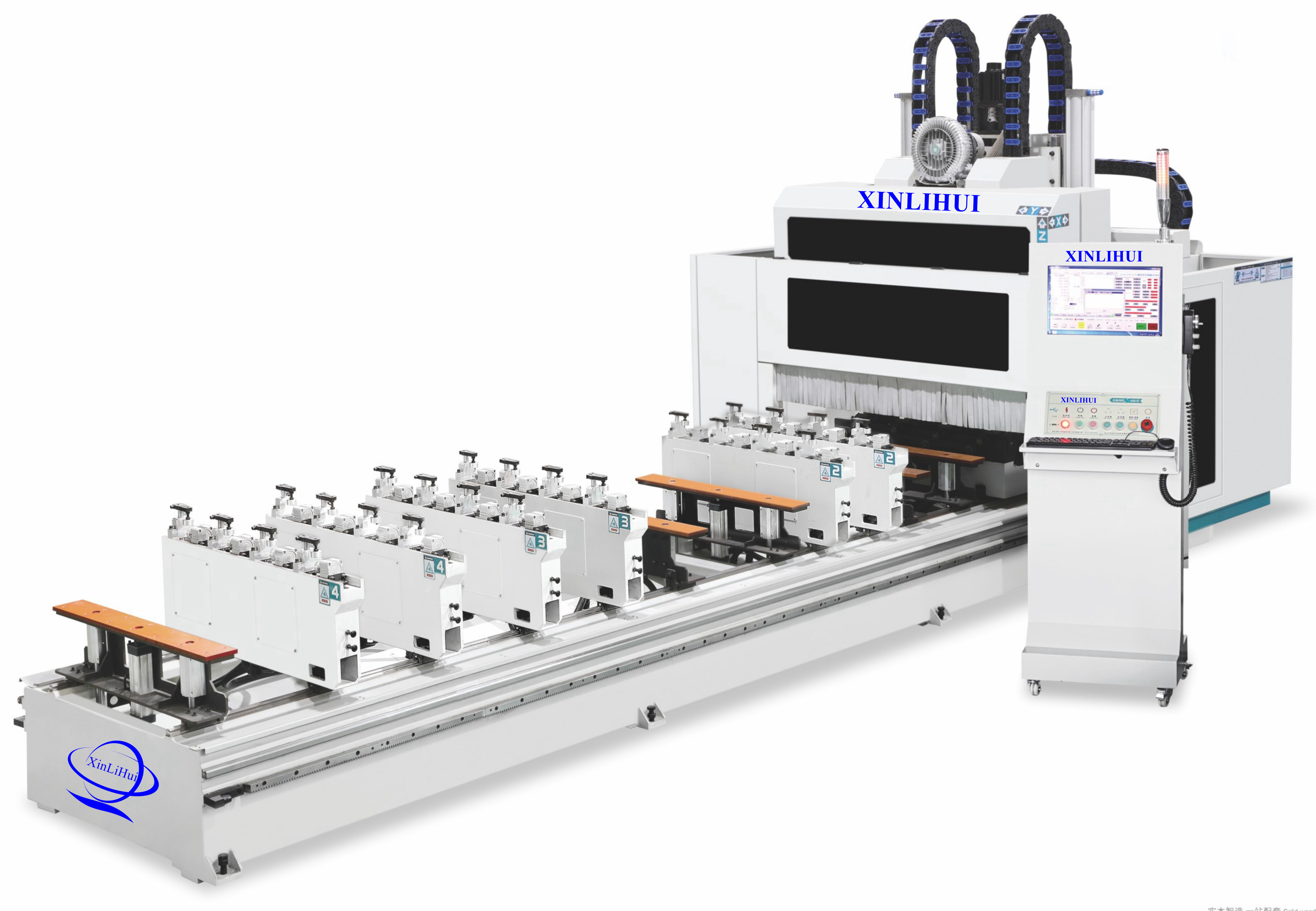

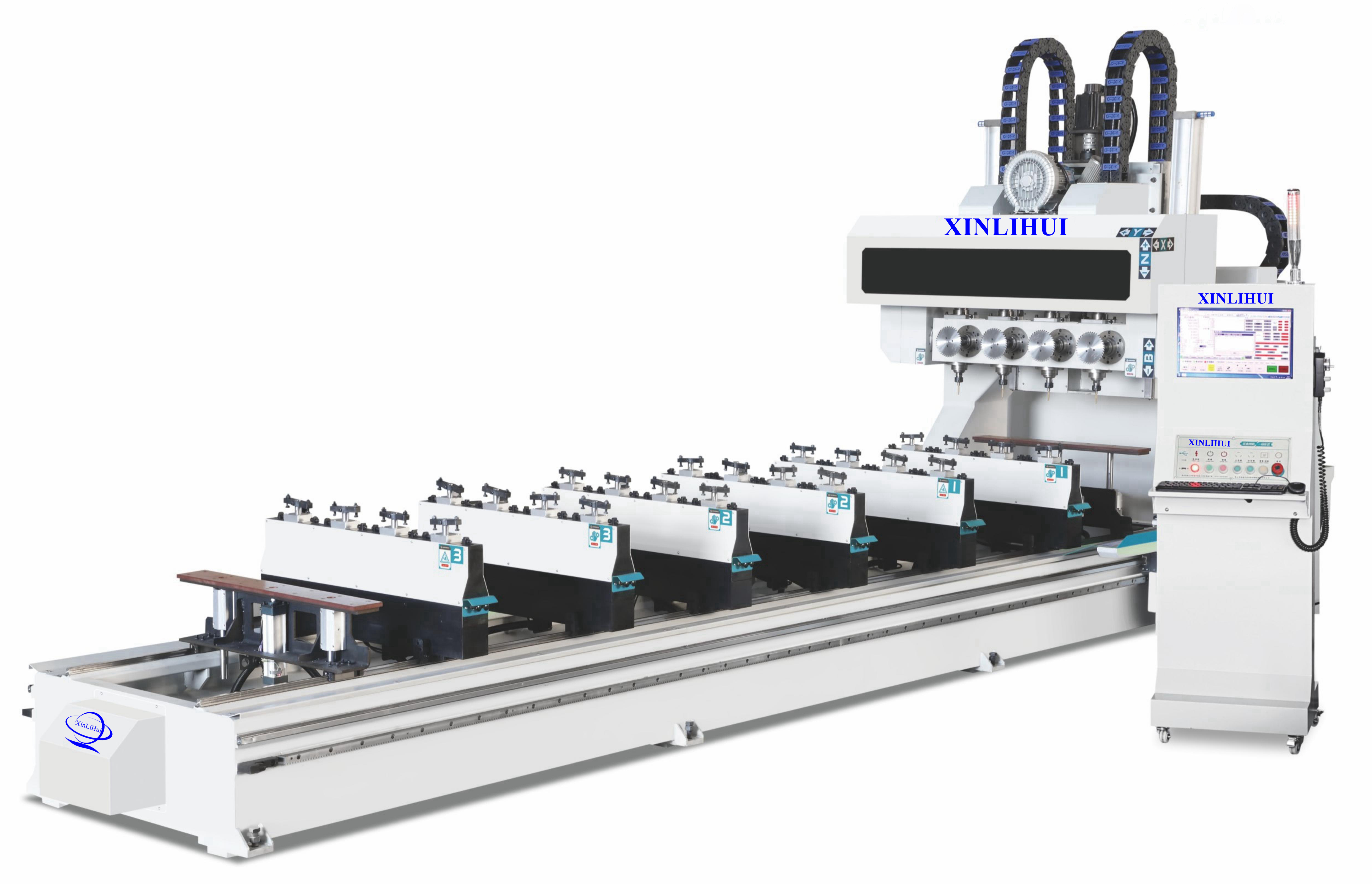

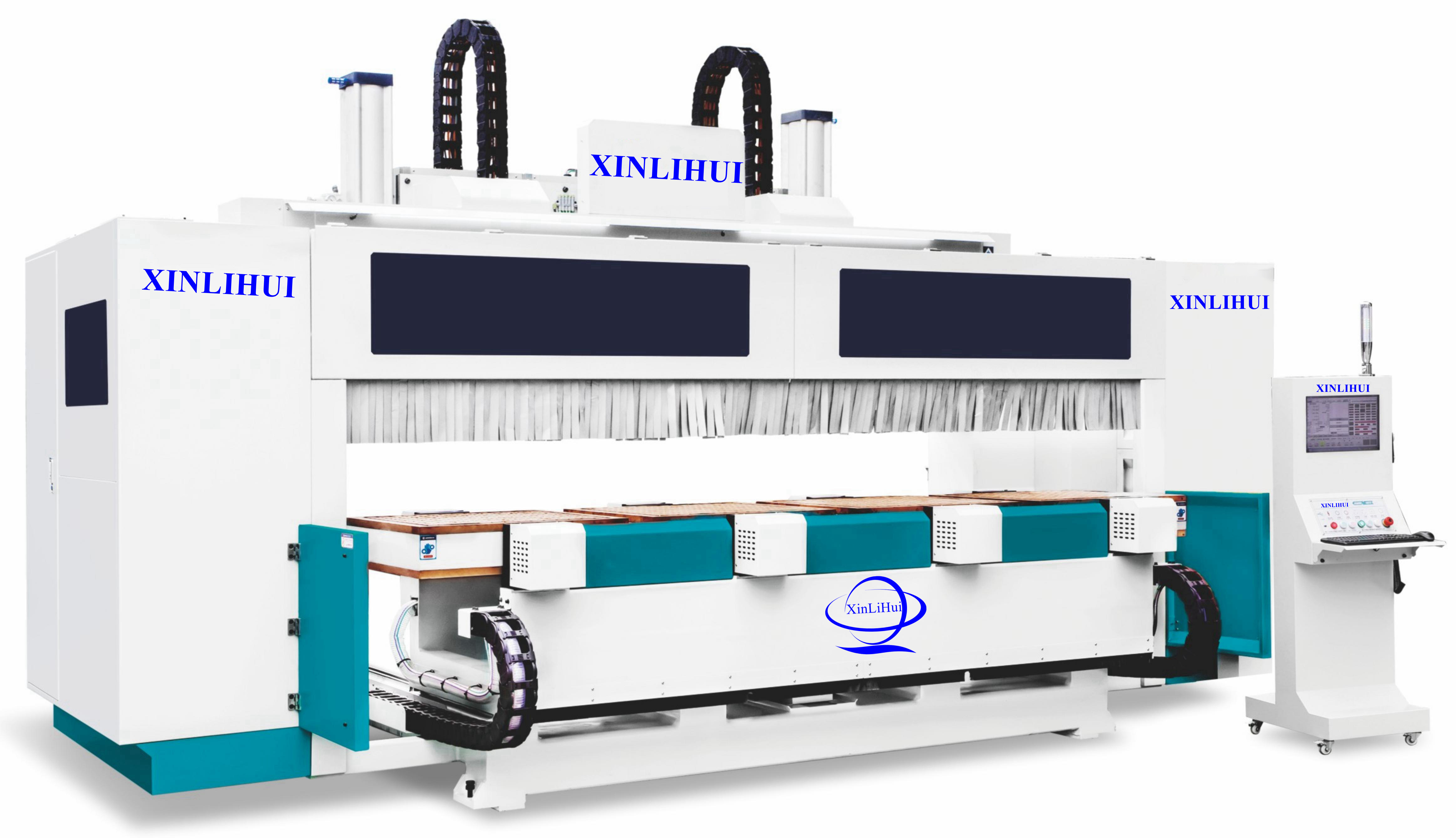

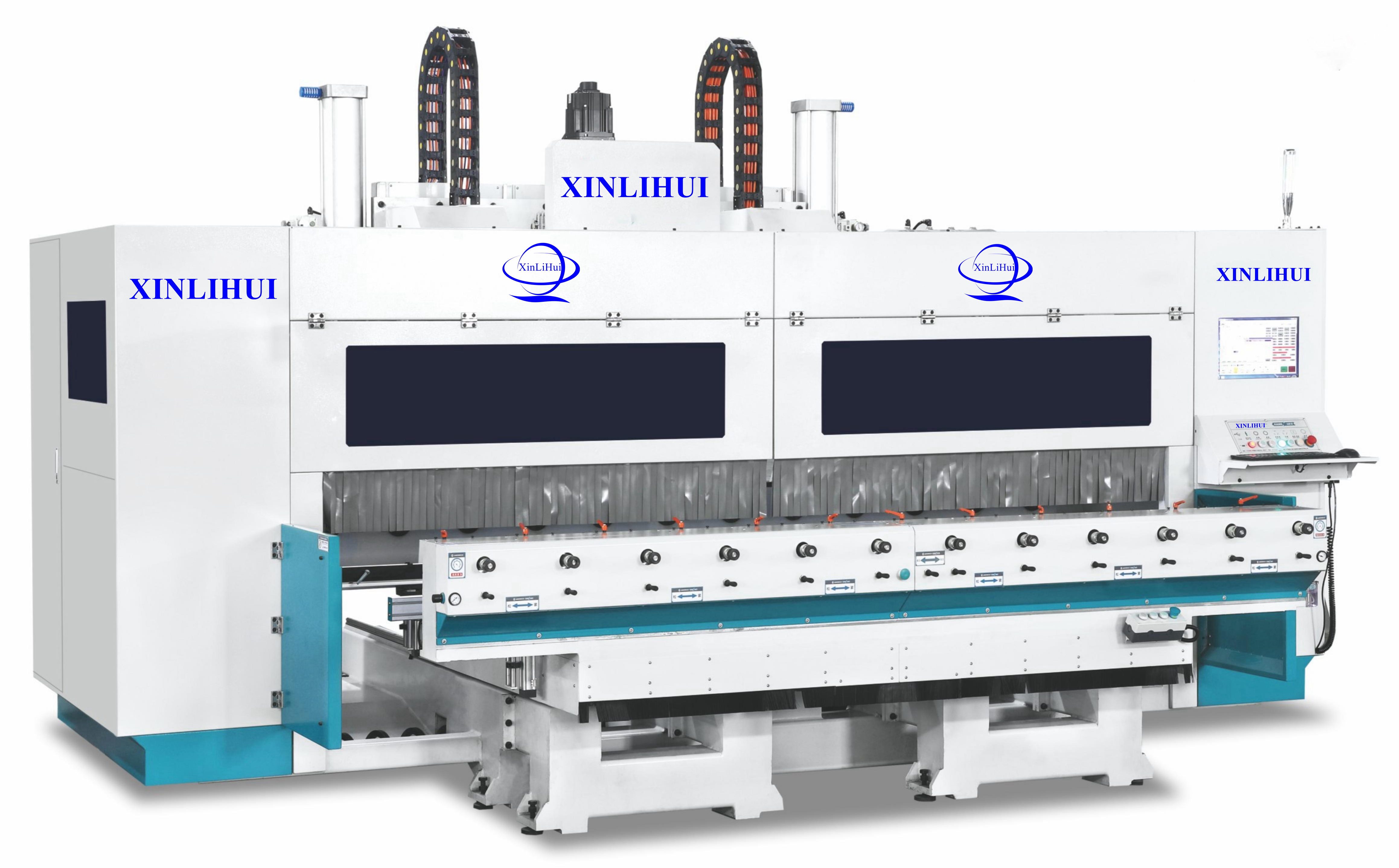

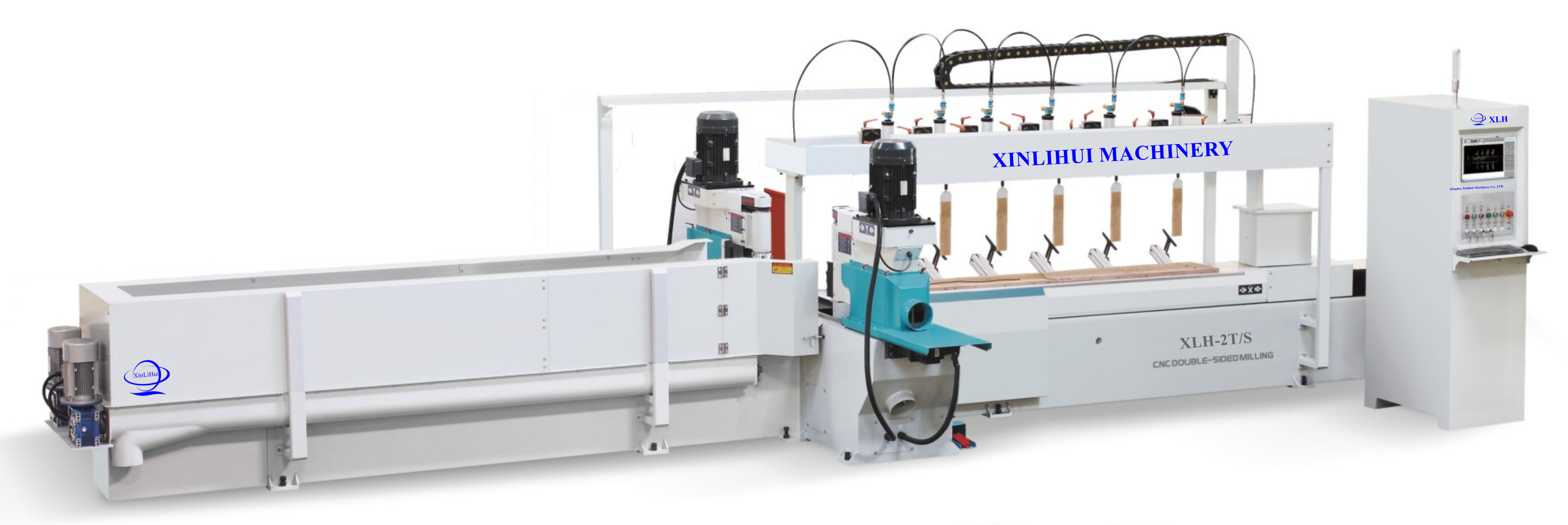

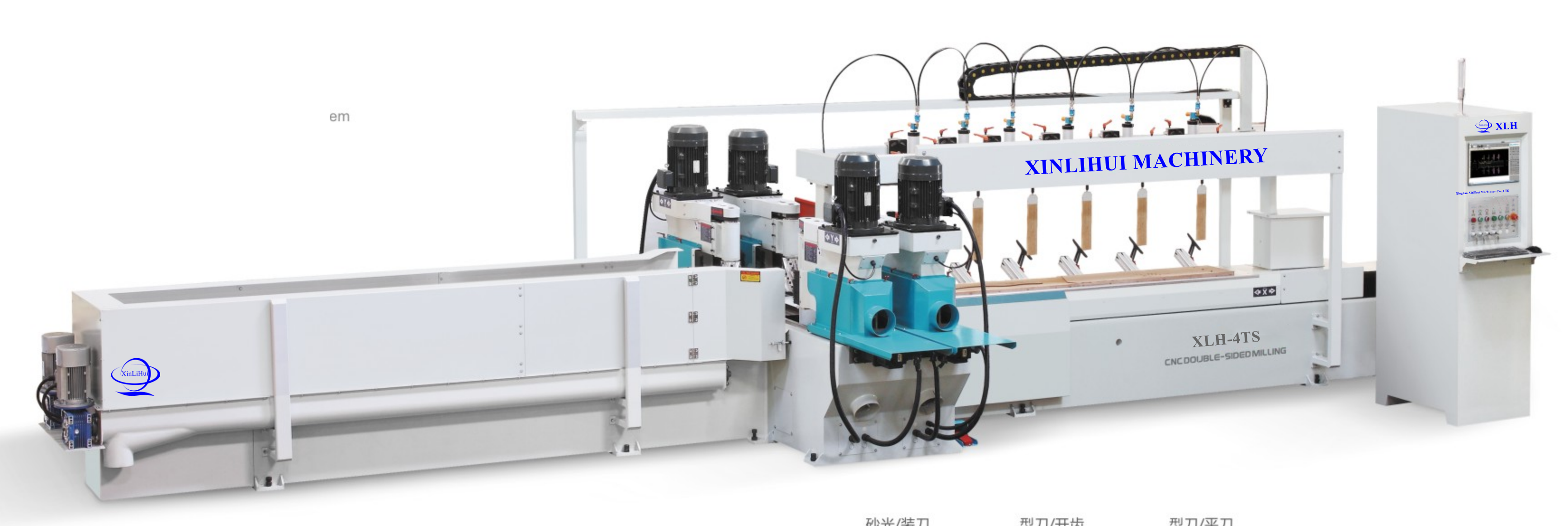

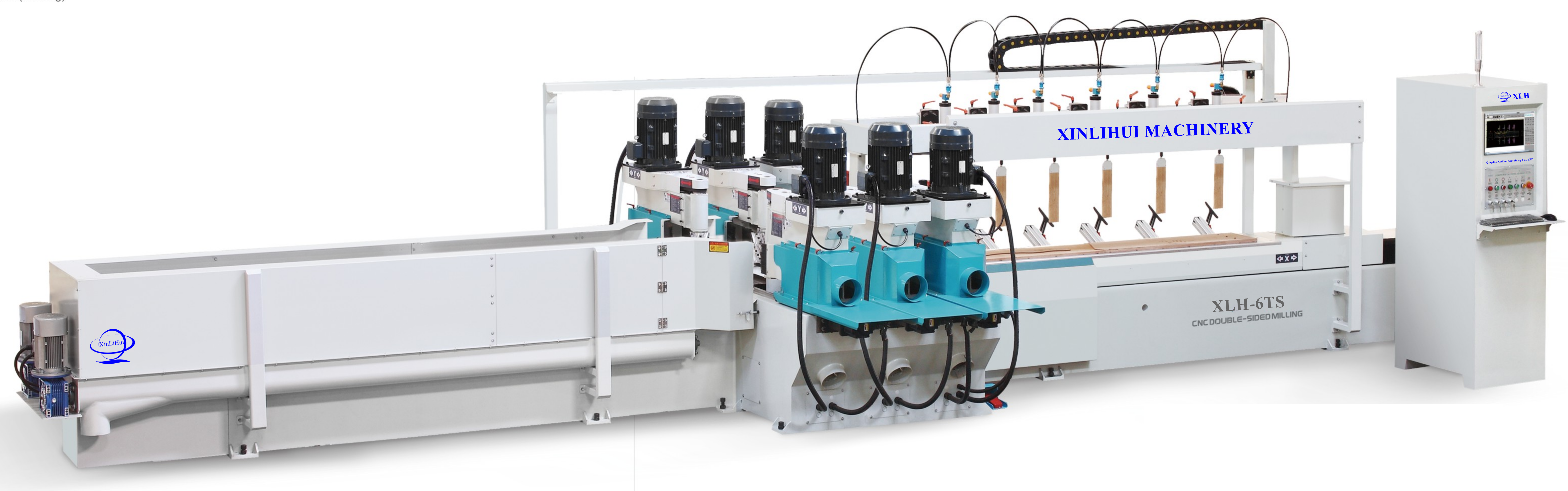

AUTOMATIC HF(RF) BOARD JOINING PRODUCTION LINE

Save glue/ Save material/ Only one person needs to operate this machine/The speed can reach120m/min

The automatic high-frequency splicing production line is mainly composed of five parts, which are wooden strip automatic feeding system, automatic gluing system,

wooden strip automatic alignment system, high-frequency splicing system and automatic palletizing system.

It can be spliced integrated panel, also can be spliced fumiture board. Only one person is required to operate a line, saving labor,

saving glue, and high degree of automation!It can be connected with upstream planning line and downstream intelligent warehousing

system to realize unattended flow operation.

Automatic feeding / Automatic gluing / Automatic layout /Automatic splicing / Automatic discharging / Automatic palletizing

It adopts the intelligent splicing system independently developed by CNHF, which is intelligently controlled and easy to leam. The production line can be operated by one person, and the labor intensity is low.

The amount of sanding is 0.5mm, which will bring you a generous retum on investment.Glue is automatically applied to eliminate manual waste and save more than 15% of glue. lt completely overcomes the

uneven production capacity caused by manual operation, and ensures that the production is efficient and stable.It is suitable for splicing integrated panel and multiple short boards. 1.5-3 minutes per beat.

Environmental protection, safety, no pollution, and can kill the eggs in the material.